P320 out-of-battery testing

P320 out-of-battery testing

Published April 28, 2023

Author: Bruce Gray

Last Updated: June 15, 2023

Can the SIG Sauer® P320 fire enough out-of-battery to induce case failure with proper ammunition? With the meteoric rise in popularity of the P320 amongst serious, high-volume shooters, we've seen reports of blown cases.

So, here's a series of firing tests and factual analysis to put these reports into proper perspective.

We ask that you do not copy and paste this post to online forums, as we may update it with additional information in the future. Most of the content from this post - and a discussion - is available on Facebook and other platforms.

Table of Contents

- Configuring a P320 for testing

- Testing with Speer Gold Dot G2 9mm Luger 147 grain ammunition

- A second round of testing with various factory new ammunition

- Extreme Testing Video - Cutting Locking Shoulder OFF

- Extreme Testing Video - Reducing Chamber Support in Barrel

- Video Podcast with Arik Levy from Firearms Nation

- Overview

- Testing Conclusion

- Revision History

TL;DR

The factory-spec P320 barrel has more than adequate case wall support to contain SAAMI-spec chamber pressures, even when fired so far out of battery that further slide-barrel retraction prevents primer strike. This is far out-of-battery beyond any mechanically plausible scenario for a normal P320 to fire by its design.

My tests should demonstrate this to anyone's reasonable satisfaction. The pistol was designed to function safely with proper spec ammo, and we increase our risk when we shoot remanufactured ammo, reloads, and the cheap stuff.

Blown cases result from out-of-spec, faulty ammunition.

Would more case wall support yield more of a margin for defective ammo? Yes, perhaps, but our goal should be to shoot quality ammo and be particularly careful in making reloads.

Configuring a P320 for testing

I set up this pistol to release the striker with enough energy to detonate a primer throughout the entire locked travel of the barrel and slide.

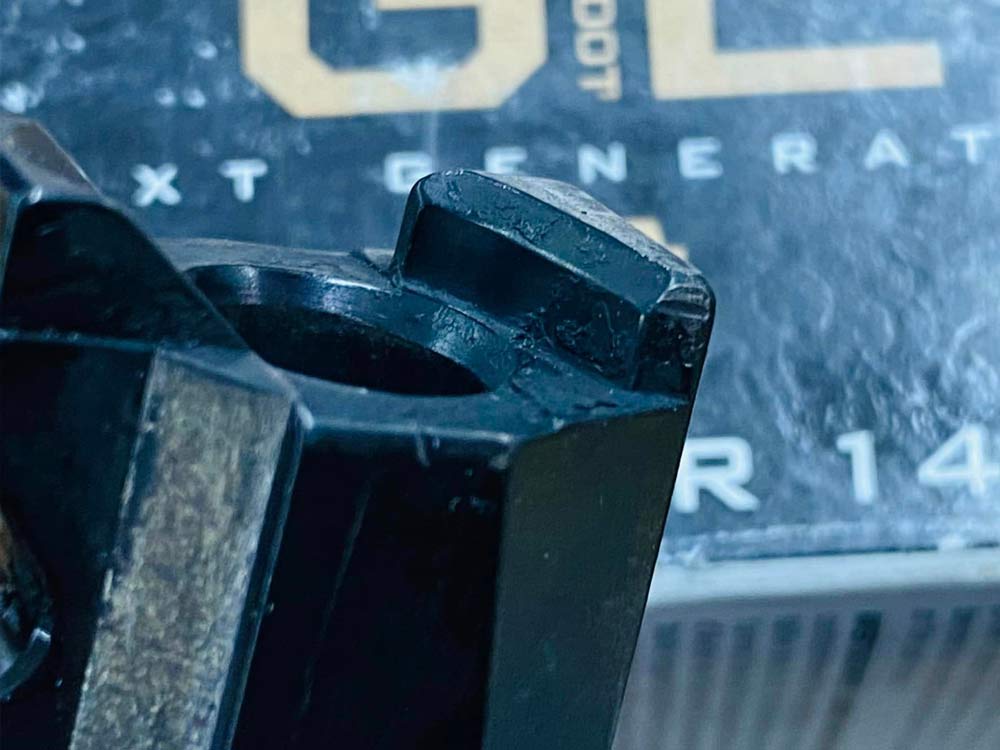

We set up this P320 parts gun to represent a worst-case scenario far exceeding a factory-spec pistol's most extreme out-of-battery condition. I paired an early 4.7" Full-Size barrel with a light 3.9" Compact slide. I fitted a short recoil spring that did not exert enough force to hold the slide closed.

The 4.7" Full-Size barrel selected for this test is from early commercial P320 production. It exhibits the substantial chamber-mouth bevel typical of most P320s.

I defeated all internal safety functions, including the following components.

- Disconnector

- Striker Lock (Photo shows this part removed)

- Original Striker Spring

The point in slide travel where the disconnector drops the trigger bar from engaging the sear in a standard P320 is typically between .085 and .125 back from full-battery.

A standard P320 striker assembly lacks the energy to ignite primers with the slide retracted after a certain point. The factory striker spring is engineered not to yield adequate ignition force unless the slide and barrel are sufficiently in battery to contain chamber pressure safely. To compensate, I installed two inter-wound striker springs to deliver enough force to ignite primers.

We then marked datum lines on tape at the following points.

- Fully in-battery

- 50% in-battery, with the slide retracted .113" from fully in-battery

- 25% in-battery (75% out-of-battery), with the slide retracted about .163" from fully in-battery

- 0 - At this point, any further retraction will pull the barrel out of engagement

The total locked travel from 0 (at which the barrel is adequately engaged with the locking shoulder to permit the striker to impact the primer) to fully in-battery is approximately .226". As noted, modifications were needed to get the P320 to fire in the 75% and fully out-of-battery positions, including defeating the internal safety functions.

Testing with Speer Gold Dot G2 9mm Luger 147 grain ammunition

A second round of testing with various factory new ammunition

Our second set of testing used a variety of ammunition, including the following. (Left to right in the photo.)

- Hornady 135 Critical Duty +P

- Blazer Brass 115 ball

- Hornady Frontier 90 XTP

- Federal 150 Syntech

- Winchester White Box 124

- SuperVel 90 HP +P

- Speer LE G2 147 (Again)

All rounds were fired at 0, or at that point in slide-barrel travel, at which further retraction will pull the barrel out of engagement. The measurement at this point is approximately .226" out-of-battery.

Despite doubling the striker springs, ignition at this slide position (0-0 lockup) was unreliable. As shown in the photos of the primer strikes, most rounds required multiple hits before igniting.

The off-center primer hits further show the marginal out-of-battery condition in the test pistol.

None of these cases exhibit signs of excessive expansion. They compare well with rounds fired from fully in battery.

Extreme Testing Video - Cutting Locking Shoulder OFF

We cut off the locking shoulder of the barrel and set it up to where it could fire at any point - or at least drop the striker at any point - at which the striker could possibly reach the primer. The pistol was set up similarly to a straight blowback design, where the breach is not locked during primer ignition.

Extreme Testing Video - Reducing Barrel Chamber Support

Next, for our extreme testing, we greatly reduced the case wall support of the P320's 9mm barrel. (Starting at about 1 minute and 45 seconds into the video.)

But first, Bruce briefly explains the previous testing where he shot the P320 significantly out-of-battery and then completed more testing without a locking shoulder on the barrel. This will help explain the "blowback design" reference in an earlier video.

Video Podcast with Arik Levy from Firearms Nation

Overview

The question is, will SAAMI spec ammo exhibit case failures in a proper P320?

By "proper," I mean a pistol that retains an as-factory-specified striker lock, disconnector timing and integrity, and hasn't had modifications that degrade safety values.

Some available modifications for the P320 degrade safety values to get a "better trigger." Grayguns components - including our triggers and trigger systems for the P320, P365, classic SIGs, and Heckler & Koch pistols - keep factory safety values in place by design.

This discussion surrounding P320s firing out of battery is not new.

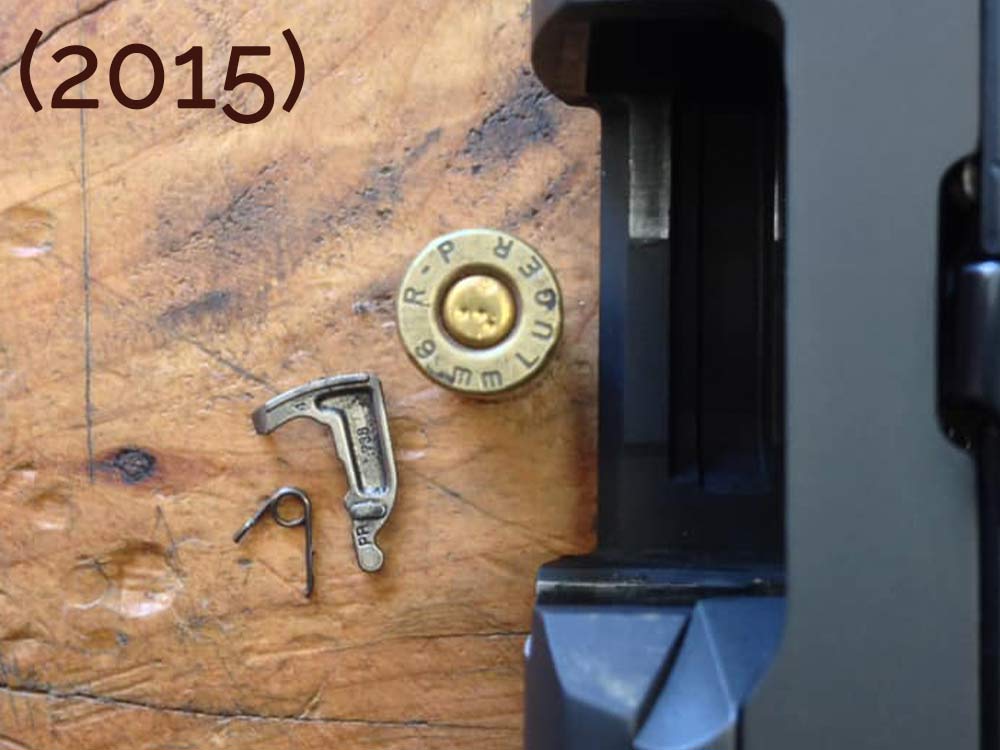

The photo was taken in 2015 from a striker-energy test. It shows primer indentations from a P320 in which I had removed the striker lock, and then released the striker to hit the primed case with the slide retracted approximately 2/3rds and further from full battery.

As designed, the striker lacked sufficient energy to ignite the primer when significantly out of its fully forward, in-battery position.

This OOB narrative is not a new one. I posted this then, but the doubters persisted because the original P320 did not have a slide-actuated disconnector. Indeed, the self-disconnecting trigger mechanism of the original P320 gave rise to this OOB failure belief.

How about more barrel chamber support?

P320 shooters who run cheap "new" ammo of unknown origin, home-reloaded, or manufacture-reloaded non-SAAMI spec ammo would possibly benefit from more chamber support as a hedge against ammo-induced failures, and that's a choice they can make. That is, nonetheless, about the ammo, not the P320 per se.

A better, more reasonable and factually informed choice is to run ammo of known quality.

No degree of additional chamber case support should be relied upon to compensate for, or reduce the risk of firing out-of-spec, defective ammunition.

Testing Conclusion

Unless a mechanically plausible, reproducible scenario that causes such failures with proper ammo and pistol is presented, I will say your P320 is safe with SAAMI spec loads. In the absence of such countervailing information, I have no factually informed reason to believe otherwise. I'm conducting these radical tests to validate or disprove my reasoned beliefs regarding this platform.

I have demonstrated out-of-battery detonations to be highly unlikely.

Fact: A proper P320 cannot fire dangerously out of battery. Why? The disconnector timing, striker lock timing, barrel lockup values, and the degree of striker travel necessary for the striker spring to have adequate ignition energy, all work against any plausible scenario for gross out-of-battery firing. In addition to these design features, slide and barrel mass play a part.

Fact: Even if an out-of-battery discharge were to occur at the minimum slide/barrel engagement necessary for the striker to contact the primer anywhere near the center, the P320 lockup system is more than capable of containing normal chamber pressure.

Fact: Many other highly successful pistols feature far shorter barrel/slide locked travel and lighter slide and barrel mass and do not blow cases.

So, why do we see these reports of blown cases in P320s?

Answer: It's caused by out-of-spec, faulty ammo.

While I'd prefer a bit more case head support as added insurance against suspect hand loads, the reality is that the P320 has zero issues with factory, SAAMI spec ammunition.

And let's be blunt: NO remanufactured or hand-loaded ammo using previously fired brass can be considered within specs. Fired cases, by definition, are suspect. Does that mean I hate reloading? Of course not; I even authored a reloading manual in 1998 that I'm rather proud of. But the fact is, reloading is fraught with risk due to a raft of potential factors. We can control for some of these (such as using powder charge warning gizmos and taking other precautions against errors), but the condition of range brass, in particular, is always unknown.

The verifiable experiences of our many shooters and law enforcement partners who have fired countless hundreds of thousands of rounds through P320s support our conclusions.

Article Revision History

- May 8, 2023 - Added Firearms Nation Podcast and Article Revision History

- May 18, 2023 - Added section: Extreme Testing Video - Cutting Locking Shoulder OFF

- June 15, 2023 - Addded section: Extreme Testing Video - Reducing Barrel Chamber Support

- June 15, 2023 - Reordered sections and fixed typo